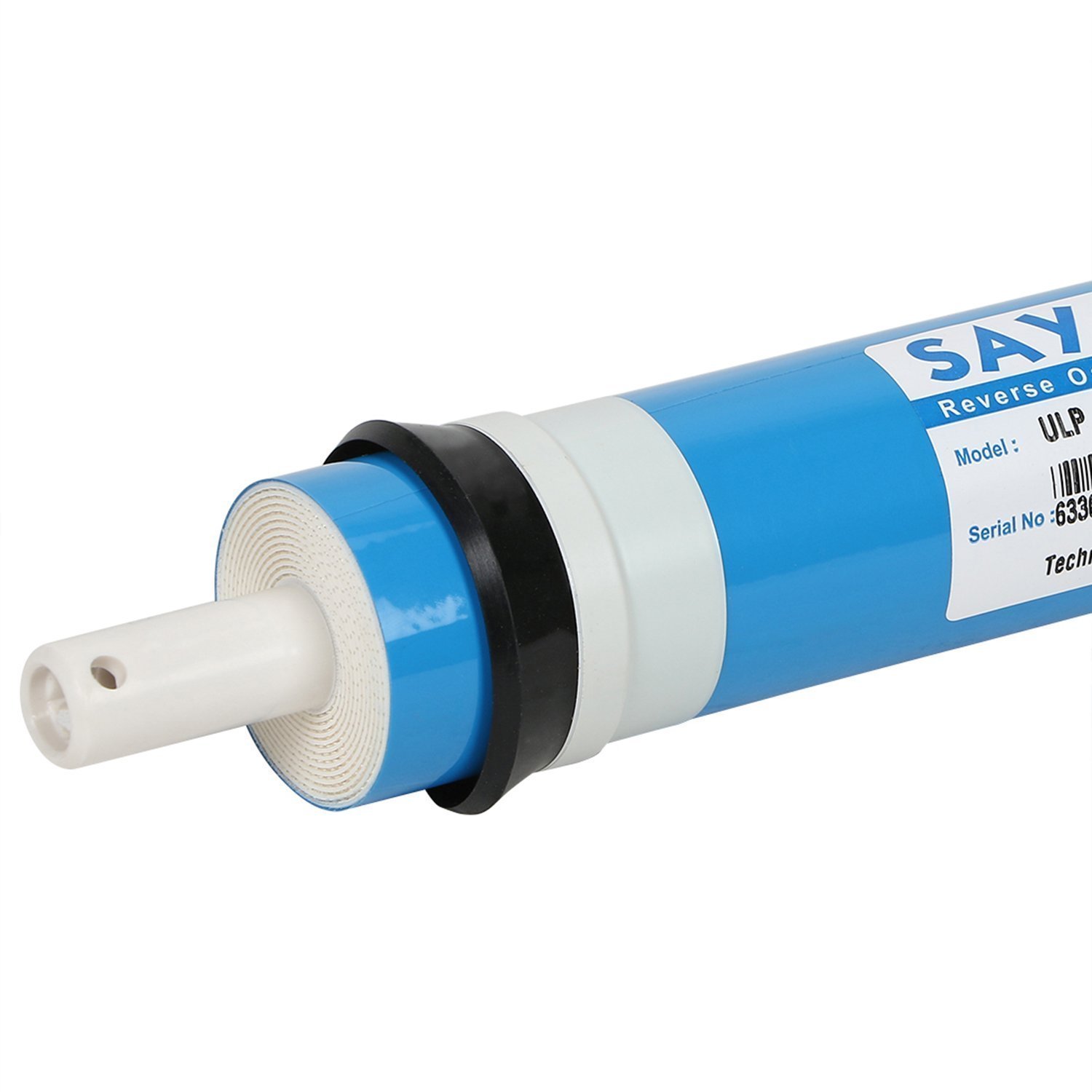

RO Membrane

Reverse Osmosis (RO) Membrane: A Filtration Workhorse

Reverse osmosis (RO) is a filtration process that uses pressure to force water through a semipermeable membrane, leaving behind

How an RO Membrane Works

- Pressure Application: Water is forced against the RO membrane under high pressure.

- Selective Permeability: The membrane has tiny pores that allow water molecules to pass through but block larger molecules, such as salts, minerals, and contaminants.

- Purification: The water that passes through the membrane is significantly cleaner and purer than the feed water.

Types of RO Membranes

There are several types of RO membranes, each with its own unique characteristics and applications:

- Thin Film Composite (TFC) Membranes: These are the most commonly used type of RO membrane, consisting of a thin, selective layer on top of a porous support layer. TFC membranes offer excellent performance, durability, and chemical resistance.

- Cellulose Acetate (CA) Membranes: CA membranes were among the first to be developed for RO applications. They are still used in some applications, but TFC membranes have largely replaced them due to their superior performance.

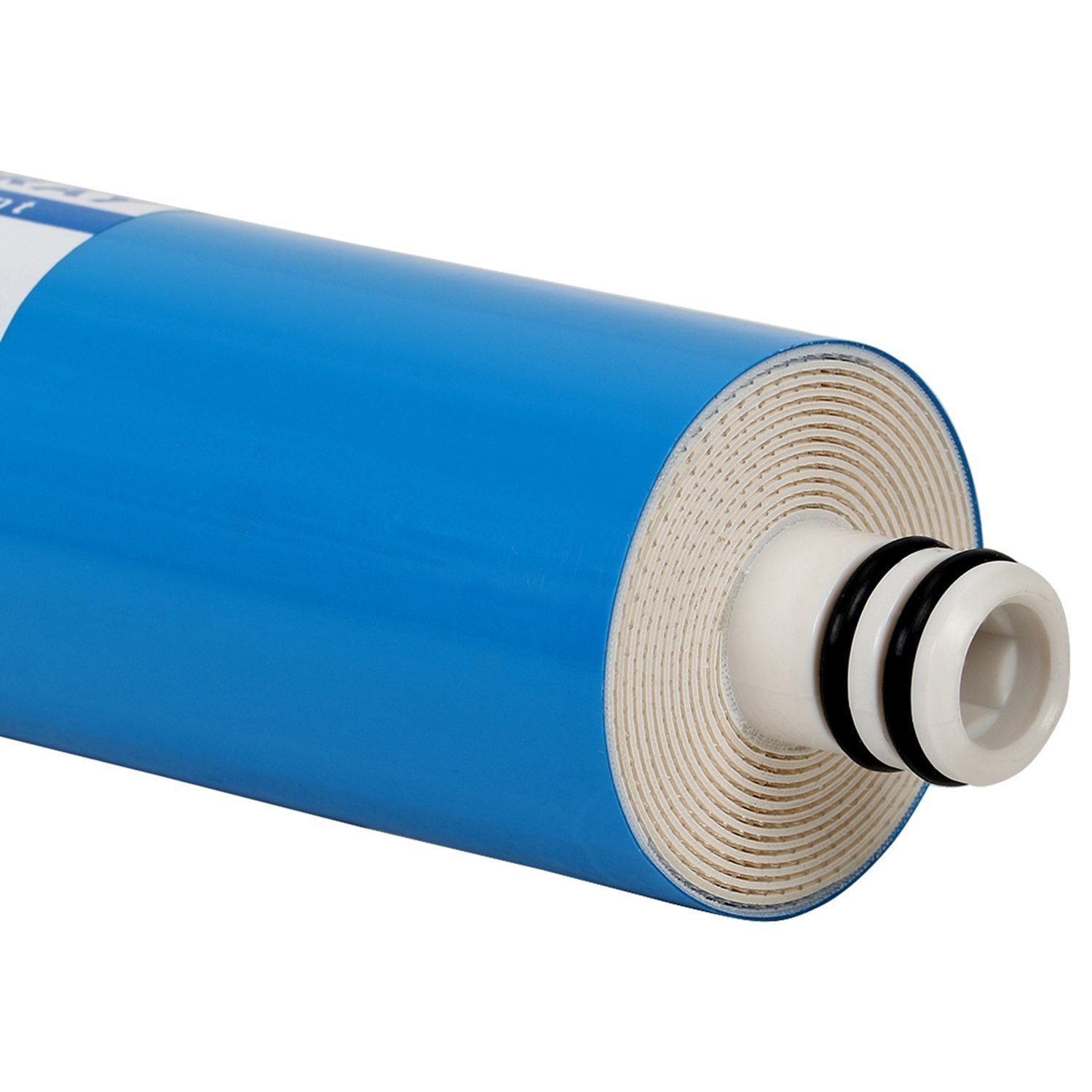

- Spiral Wound Membranes: These membranes are wrapped around a central core, creating a spiral structure that maximizes surface area and filtration efficiency.

RO Membranes

Factors Affecting RO Membrane Performance

Several factors can affect the performance of an RO membrane, including:

- Feed Water Quality: The quality of the incoming water can significantly impact membrane performance. High levels of contaminants can reduce membrane life and filtration efficiency.

- Operating Pressure: Higher pressure generally leads to higher water recovery rates but can also increase membrane fouling and scaling.

- Temperature: Temperature can affect membrane permeability and fouling. Higher temperatures can increase permeability but may also accelerate fouling.

- pH: The pH of the feed water can influence membrane performance and fouling. Extreme pH values can damage the membrane.

Applications of RO Membranes

RO membranes are used in a wide range of applications, including:

- Water Treatment: For desalination, brackish water treatment, and municipal water purification.

- Industrial Processes: For wastewater treatment, boiler feedwater purification, and food and beverage production.

- Electronics Manufacturing: For ultrapure water production used in semiconductor manufacturing.

- Medical Applications: For dialysis and pharmaceutical production.

Would you like to know more about a specific type of RO membrane or its applications?