High Purity Water System

High Purity Water Systems: A Critical Component in Industries

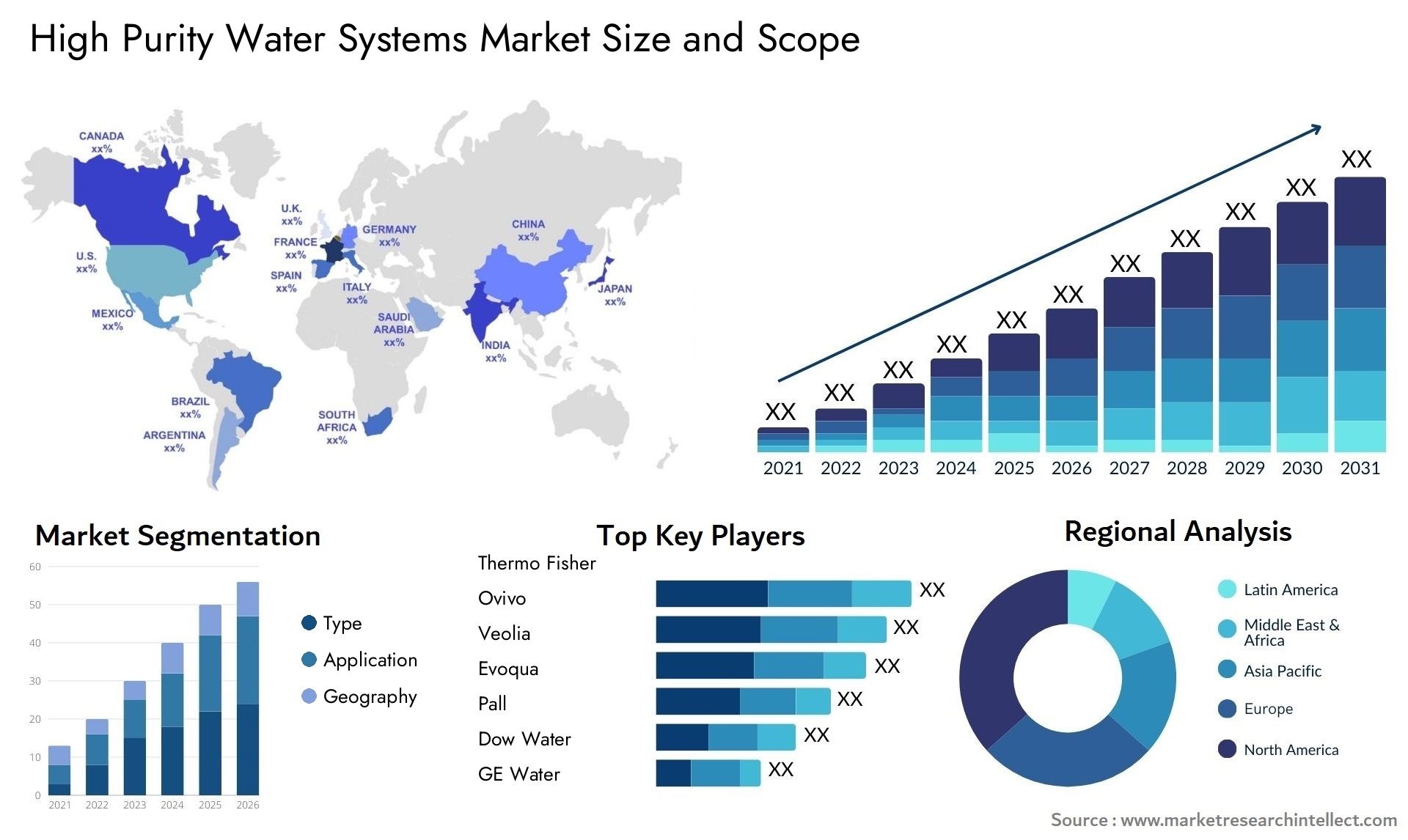

High purity water systems are essential for industries that require water with extremely low levels of impurities, such as pharmaceuticals, biotechnology, semiconductor manufacturing, and research laboratories. These systems utilize advanced filtration and purification technologies to produce water that meets stringent quality standards.

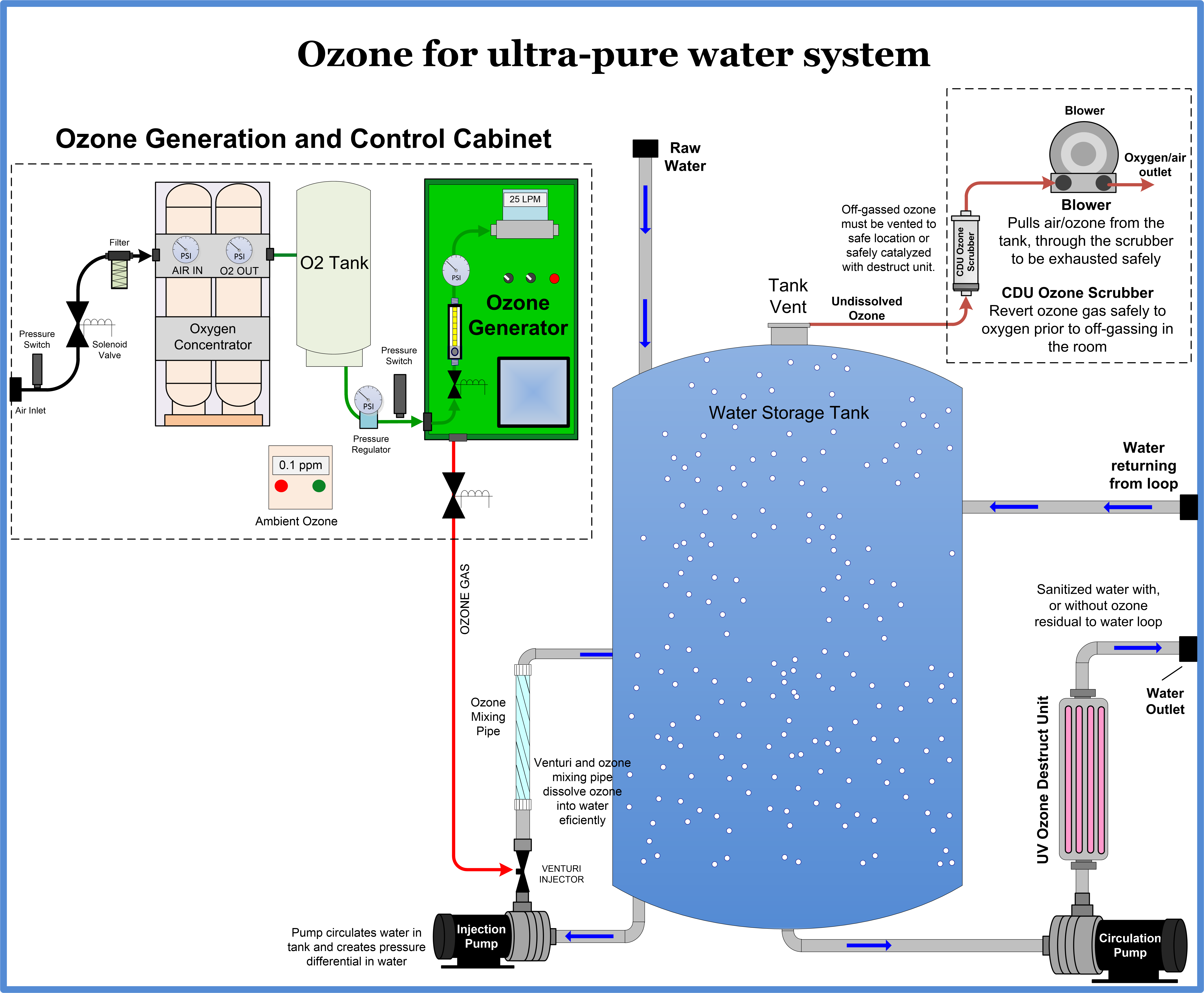

Components of a High Purity Water System

A typical high purity water system consists of several key components:

- Pre-treatment: This stage involves removing larger particles, turbidity, and other contaminants from the incoming water source using processes like filtration and softening.

- Deionization: This process removes mineral ions, such as calcium, magnesium, and sodium, from the water using ion exchange resins.

- Reverse Osmosis: This technology uses pressure to force water through a semipermeable membrane, leaving behind impurities on one side.

- Ultrafiltration: This process removes larger molecules and particles from the water using a membrane with smaller pores.

- Carbon Filtration: This stage removes organic contaminants, such as volatile organic compounds (VOCs) and chlorine, from the water.

- Final Polishing: The final stage involves removing any remaining impurities using technologies like ultraviolet (UV) sterilization and microfiltration.

Reverse Osmosis System

Applications of High Purity Water Systems

High purity water systems are used in a wide range of industries, including:

- Pharmaceutical Manufacturing: For the production of pharmaceuticals, injectables, and other sterile products.

- Biotechnology: For research, development, and manufacturing of biological products, such as vaccines and enzymes.

- Semiconductor Manufacturing: For the production of semiconductor wafers and other electronic components.

- Research Laboratories: For various scientific experiments and analyses.

- Food and Beverage Industry: For the production of beverages, such as bottled water and carbonated drinks.

Quality Standards

High purity water systems must meet specific quality standards to ensure the integrity of products and processes. These standards often include:

- Resistivity: Measures the ability of water to conduct electricity, indicating the level of ionic impurities.

- Total Organic Carbon (TOC): A measure of the amount of organic matter present in the water.

- Particle Count: The number of particles of a certain size per unit volume of water.

- Bacteria Count: The number of bacteria present in the water.

- Endotoxin Levels: A measure of the presence of bacterial toxins.

By adhering to these stringent quality standards, high purity water systems play a vital role in ensuring the success and safety of various industries.

Would you like to know more about a specific component or application of high purity water systems?